Many repair jobs fail because we do not pick the right bearings. I feel the frustration of repeated breakdowns. I see a better way to solve this.

Tri-metal bearings1 use layered designs that carry heavy loads. Bi-metal bearings2 focus on simpler construction and steady performance. Their difference lies in how they manage load, heat, and friction.

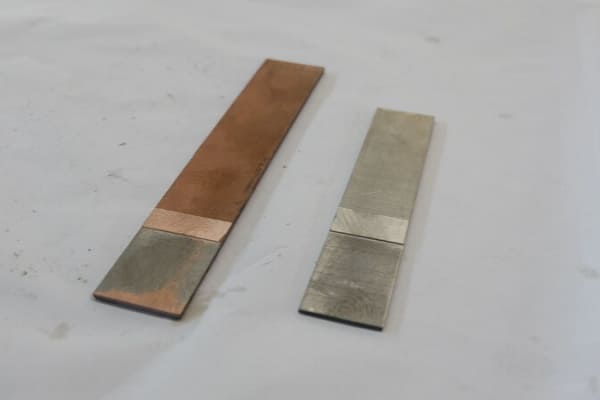

Tri metal Bi metal Bearing

I have seen many people unsure about bearing materials. They jump straight into repairs without enough thought. I believe we should explore each material in detail. That helps us avoid future problems and meet the right standards.

What is tri-metal bearing material ?

I used to wonder why some bearings wore out quickly. Then I looked deeper. I noticed tri-metal bearings have extra layers that help them resist wear and handle heavy loads.

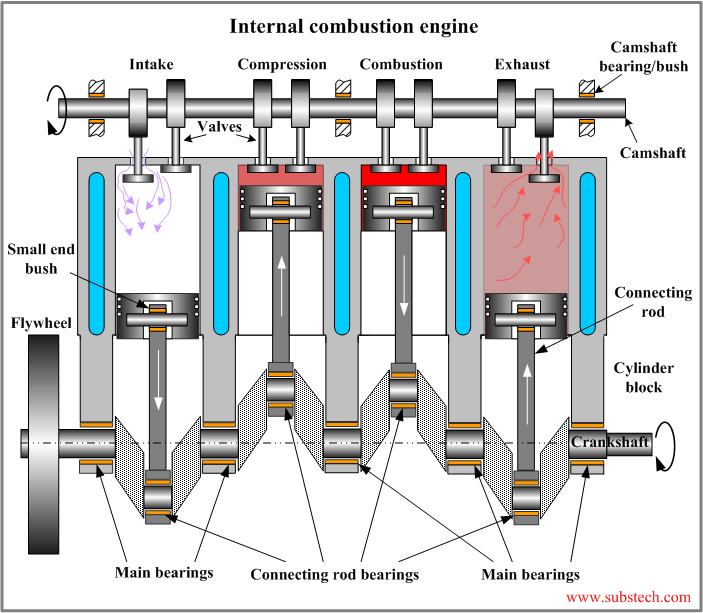

Tri-metal bearings usually have a steel backing, a copper or bronze layer, and a softer top layer. This helps with resilience and reduces friction. They are common in high-stress engines.

Tri metal Bearing

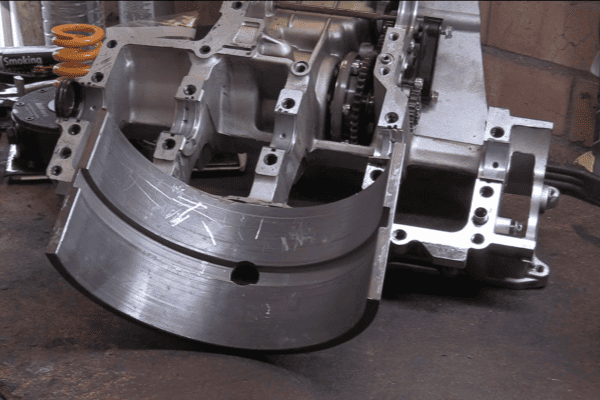

I remember my first time handling tri-metal bearings. I was working on a diesel engine that ran under extreme stress. The bearings kept failing, so I researched why. I learned that tri-metal bearings have three main layers: a strong steel base, a mid-layer that often includes copper or bronze, and a thin surface layer of softer alloy or babbitt. Each layer has a role in distributing the load, reducing friction, and dealing with high temperatures. That design can manage more impact and allow for slight misalignments. It also helps dissipate heat.

I saw that these layers protect the crankshaft from scoring or damage when lubrication is not perfect. The softer top layer catches small contaminants and prevents deeper scratches. This feature can extend engine life because it shields more expensive engine parts from wear. Still, I learned that tri-metal bearings can cost more and might require higher-quality lubrication. Their design is advanced, so they might not be necessary for engines that do not experience high loads or speed extremes.

To better show the structure of a tri-metal bearing, I use a simple table:

| Layer | Material Composition | Key Advantage | Common Concern |

|---|---|---|---|

| Steel Base | Steel backing | Provides core strength | Risk of corrosion if not coated properly |

| Mid-Layer | Copper or bronze alloy | Helps with heat transfer | Higher cost than bi-metal |

| Overlay | Softer alloy (babbitt) | Low friction, scuff protection | Thinner layer that can wear out if lubrication is poor |

I tested tri-metal bearings in engines that ran extended hours in tough conditions. Those engines had fewer bearing failures when I maintained good oil conditions. If I had used a cheaper alternative, I might have saved some money up front. However, the downtime and extra repairs would have cost more in the long run. This is why I place a high value on choosing the correct bearing. It prevents repeated breakdowns, preserves engine components, and gives me peace of mind.

What is bi-metal bearing material?

I used to see many shops stock only one type of bearing. That did not feel right to me. I wanted to know if bi-metal bearings were enough for most applications.

Bi-metal bearings have two layers: a steel backing and an alloy layer. They are simpler and work in many moderate-stress engines.

Bi-metal-bearing

I have installed bi-metal bearings in passenger cars and light trucks that do not face very high stress. I like their straightforward construction. The steel backing gives the bearing a solid foundation, while the alloy layer—often an aluminum or lead alloy—helps reduce friction. This design can be cost-effective, especially in engines that do not run at extreme speeds or pressures.

I have also seen these bearings in smaller marine engines and in certain industrial machines. The idea is that they handle moderate loads well. They are not always the best choice for severe applications, but they can last a long time if the engine is maintained properly. One key point is that bi-metal bearings rely heavily on good oil film to reduce metal-to-metal contact. If the oil pressure drops or contaminants enter, the aluminum or lead layer can wear faster.

Here is a table comparing core features of bi-metal bearings:

| Layer | Material Composition | Key Advantage | Common Concern |

|---|---|---|---|

| Steel Backing | Steel base | Basic structural strength | Can corrode if poorly coated |

| Alloy Layer | Aluminum or lead alloy | Good friction control | Susceptible to wear if lubrication fails |

I remember one engine rebuild where I tested bi-metal bearings on a daily driver car. The car was never pushed beyond normal highway speeds. The bearings performed well for years. They did not show major signs of wear, even after many miles. On the other hand, when I used bi-metal bearings on a performance engine, I noticed signs of stress after a few thousand miles. This taught me that application matters. You have to consider factors like load, engine speed, and temperature. Otherwise, you might face premature bearing failure.

When should use tri-metal material bearing, when to use bi-metal material bearing?

I used to mix bearing materials without considering engine demands. That led to rework. Now I know better. I focus on engine requirements first.

Tri-metal bearings suit higher-performance, high-load engines. Bi-metal bearings are good for moderate workloads and standard operating conditions. The choice depends on stress levels, engine output, and maintenance habits.

Material Choice

I think the decision starts with engine specs. If the engine is turbocharged, runs high RPMs, or is frequently under heavy load, tri-metal bearings might be the safer choice. They handle stress, distribute heat effectively, and resist wear. This is why I see them in racing engines, heavy-duty trucks, or industrial machines that run 24/7. The tri-metal layers provide extra protection against friction spikes if oil flow drops for a moment. That extra margin can prevent catastrophic failure.

Bi-metal bearings are still useful if I am working on a stock engine that rarely sees high stress. In normal driving, the simpler bi-metal design can last a long time. The steel backing, combined with an aluminum or lead-based overlay, reduces friction and withstands routine RPM ranges. The cost is usually lower, and they are easier to source. Many OEM manufacturers use bi-metal bearings in their standard models because the performance demands are within normal range.

I also consider personal habits. If I maintain regular oil changes and use quality lubricants, bi-metal bearings can work well. But if I anticipate a lot of heat, heavy loads, or maybe less frequent oil changes, then tri-metal bearings add a layer of safety. Some friends ask if they should upgrade to tri-metal bearings even if their engine is basic. I remind them that higher-spec bearings can help if they plan on performance upgrades or towing heavy loads in the future. It might be an investment that pays off later.

I recall an engine rebuild where the original bearings were tri-metal. I thought about using cheaper bi-metal replacements. Then I remembered that in engine repair, we should follow the standard of the original engine parts. Choosing the same material helps maintain performance. If I downgrade the bearings, I might face more wear and tear or even immediate failure. The small savings would not be worth the risk. In my experience, always match or exceed the original specs when it comes to bearings. This keeps everything balanced and prevents downtime. The same principle applies to many parts of an engine. If the factory chose tri-metal bearings for good reasons, I prefer not to change that.

Conclusion

Choosing the right bearing type depends on your engine’s load, speed, and reliability needs. I match or exceed original specs to avoid needless repairs.

-

Explore the unique layered designs of tri-metal bearings and how they excel in carrying heavy loads, offering insights into their superior performance. ↩

-

Discover the simpler construction of bi-metal bearings and their effectiveness in maintaining steady performance, crucial for various applications. ↩